No planet B

There is only one planet Earth, yet by 2050, the world will consume as if there were three. Investigations by the EU showed some alarming projections: global resource consumption is expected to double in the next 40 years, and annual waste generation is likely to increase with 70% by 2050. The construction industry accounts for about 50% of all extracted resources, and generates roughly 35% of the EU's total waste.

100% circular in 2050, are you ready?

The only way forward is with a smaller footprint, and our footprint can only shrink by using less resources and generating less waste. This is where circular processes are gamechangers: turning waste into a resource tackles both problems at once.

At REPEAT® Materials, we believe in protection our environment by contributing to a more sustainable construction industry. Our goal is to offer sustainable building materials, at the same cost and performance as the state-of-the-art alternatives.

1

Why we do it

2

How we do it

Circular Design

To ensure we can keep reusing the same resources, circular manufacturing processes are needed. At REPEAT Materials®, we do this by measuring our impact and taking into account different aspects of circularity:

-

The origin of our materials

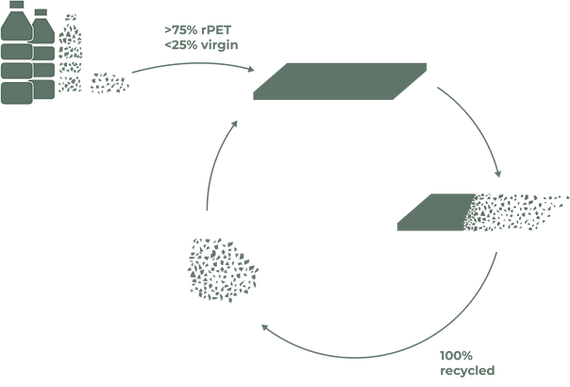

At the moment, our panels make use of around 75% recycled PET, with the rest being virgin PET. While this is not our desired 100%, this means that we only use 1/4th of the resources we would use otherwise

-

A mono-material

Every layer in our panels is PET, no metals, no glass-fibers, no wood. This means that we can eliminate the complex (and costly) separating and sorting processes from our recycling. Damaged panels, cut-offs or even milling dust, everything is PET and can be recycled as easily as a plastic bottle.

-

The end-of-life scenario for our products

As our waste is not "polluted" with other materials, we can re-cycle it into new panels, instead of having to down-cycle it into lower-quality products. This way we can close the loop, and turn the linear pattern into a circular one, saving as many materials as possible from being dumped or incinerated.

-

The disassembly of our products

In addition to considering the origin and future scenario of our materials, we also think about the disassembly of our products. The more easily a product can be disassembled, the better it can be reclaimed and used modularly. To achieve this, we have designed a special PET click system that simplifies the disassembly of our panels.

-

Local production

Trying to reduce the impact of transport and shipping as much as possible, REPEAT® Materials are entirely local, Belgian products. The panels are made locally, using Belgian materials, which were made with local waste. These short supply lines greatly reduce the time, cost and environmental impact connected with transport.

A typical REPEAT Materials® panels contains about 625 recycled PET bottles*

*or its weight-equivalent in other PET waste.

Measuring our Impact

Measuring is knowing! That’s why at REPEAT® Materials, we have had our environmental impact and product circularity quantified by recognized, verified agencies, and we publish this data openly.

Measuring our environmental impact

REPEAT® Materials has conducted a life cycle assessment (LCA) in accordance with ISO 14025 and the European standards 15804+A1 and 15804+A2, which provide full transparency regarding the environmental profiles of our products. This LCA data has been verified by a recognized party and can be found in the Environmental Product Declarations (EPD) reports. LCA data is available in:

Measuring our circularity and ability to disassemble

REPEAT® Materials has had a validated Product Circularity Index (PCI) calculated for its products. The PCI score quantifies the degree of circularity at the product level, considering the origin, future scenario, lifespan, and disassemblability of the product.

This circularity assessment provides valuable information for our customers and serves as evidence for certifications such as BREEAM-NL or LEED. The results of the PCI assessment are included in the BCI Gebouw database:

Use the documents below to see how many credit points you can receive when using REPEAT Materials in certifications such as BREEAM-NL or LEED. In this way, we ensure transparency and contribute to a more sustainable future.

3

What we aim for

REPEAT® Materials aims to work on the cradle-to-gate portion of our life cycle to reduce its environmental impact while keeping the bar straight on the product’s functionality.

The 17 SDGs aim to make significant progress on global economic, social, and environmental challenges by 2030.

At REPEAT materials, we aim to contribute to SDG 11 to make cities and human settlements inclusive, safe, resilient and sustainable. Since the entire panel is rPET, it can be recycled without any complex sorting or separating processes. Any discarded panels or cutting waste can easily be recycled into new panels, bottles, or other PET products. In this way, we reduce the total urban solid waste generated by cities.

At REPEAT Materials we aim to contribute to SDG 12 to ensure sustainable consumption and production patterns. All our panels consist entirely of at least 75% recycled PET plastic. In this way, we contribute to sustainable management and efficient use of natural resources.

At REPEAT Materials we aim to contribute to SDG 13 to take urgent action to combat climate change and its impacts. We quantify our impacts to address our sustainability and environmental protection, Our Life Cycle Assessment (LCA) results show that REPEAT Materials carbon footprint is significantly reduced compared to the main competitive panels. In this way we integrate climate change measures into our policies, strategies and planning.